The high degree of cross-pollination between our main disciplines, Design & Engineering and Research & Development, results not only in innovative ships, but in equally innovative research projects. Sometimes they intertwine, as is the case for the LNG powered dredger Ecodelta and the Interreg-funded research project CO2ASTS (CO2 capture, storage and transfer in shipping).

Onboard Carbon Capture

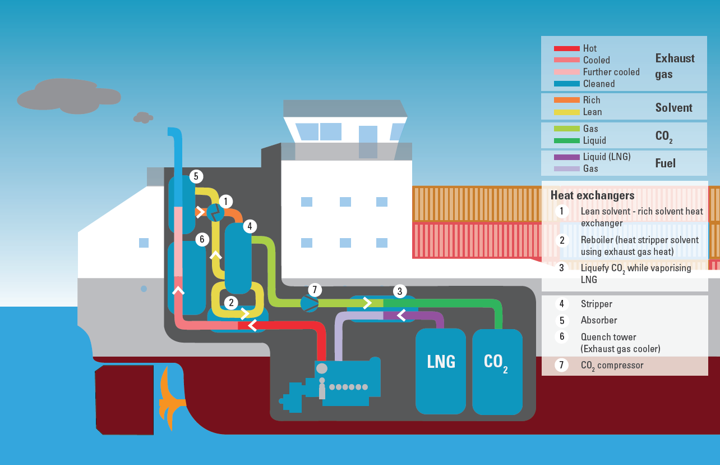

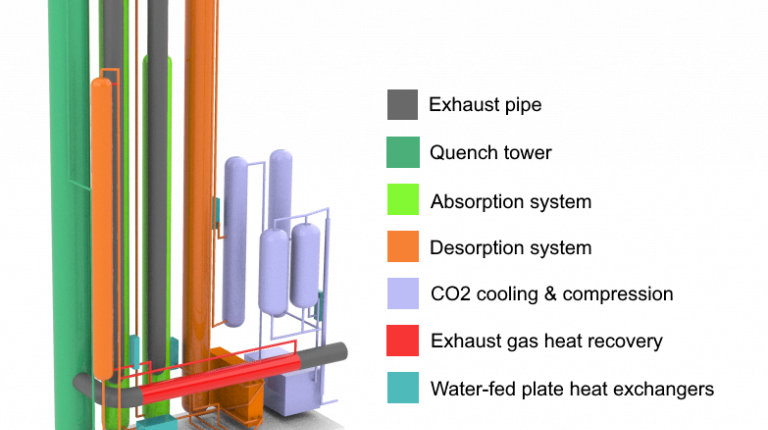

In addition to the use of LNG, the subject of carbon capture has been gaining more general acceptance as a way of meeting the emission targets. The feasibility study CO2ASTS focused on Ship Based Carbon Capture and Storage for inland and short sea shipping using LNG as a fuel with the objective of gaining insight into the main cost drivers and possibilities for minimising the costs per kg of CO2. This has been investigated and tested on the basis of three use cases. It is therefore not surprising that the Ecodelta, in addition to a sea river cargo vessel and a cruiseship, served as a use case within this research project.

LNG-Powered Dredger Ecodelta

The Ecodelta, the first Dutch dredger on LNG, is a model of innovation. The optimised hull for minimum fuel consumption, tailored to the bunker interval and the integration of an LNG tank in the design are the most important innovations. By application of LNG technology, the vessel was already in compliance with the regulations for emission reduction that came in force in January 2020.

The process of building this ship had an intensive preliminary phase. We participated in the feasibility study ‘Dredging on LNG’ (TKI Gas) as early as 2013. The first discussions about a newbuild dredger took place in 2015 and the ship was delivered at the end of 2018. This lengthy process also had to do with the specific question and requirements set by client Bagger & Aannemingsmaatschappij Van der Kamp for a dredger for the port of Rotterdam. The final goal of the port of Rotterdam is to become the most sustainable port by replacing fuel oil with LNG.

CO2ASTS

The results of the feasibilty study were presented at Europort 2019. The most important conclusion from the research, for a vessel such as the Ecodelta, is the good adaptability of an onboard carbon capture system through retrofitting due to the LNG as fuel and the space on board for the installation. The Ecodelta would even be H2 ready to achieve a closed carbon loop. The actual application of retrofits remains highly dependent on the CAPEX, although this could be reduced by smart installation solutions.

Re-using Captured CO2

The captured CO2 can be re-used in food-industry and greenhouses. For the future of the ‘Hydrogen-economy’ it is expected that the containerized liquified CO2 will be a valuable feedstock for the production of synthetic carbon fuels: when large quantities of hydrogen (H2) will be produced using solar- or (excessive) wind-energy, synthetic fuels can be produced out of H2 and CO2 , like methane (CH4 ) or methanol (CH3OH). These synthetic fuels can be the ‘hydrogen-carriers’ that can be bunkered in a ship (better than liquid or pressurized H2) and Liquified Synthetic Methane CH4 is the same molecule as the main component of LNG (abt. 80% CH4). It is also liquid at minus 163 Celcius and can be bunkered in exactly the same tank with the same systems as the actual LNG-systems. The infrastructure on board and on land will stay the same and the actual developing LNG-infrastructure and ships can still be utilized in the ‘Hydrogen-economy’ of the future, providing the CO2 is captured and re-used, creating a non-fossile CO2 cycle.

The research continues…

The CO2ASTS feasibility study contributes to forming a long-term vision on the subject of Carbon Capture. The conclusions of the CO2ASTS form the input for the TKI project DerisCO2 in which TNO and Heerema also participate. The crane ship Sleipnir from Heerema will be retrofitted as part of this pilot project to create a circular fuel loop. The project has recently started and the first results are expected halfway through 2020.

Curious or do you have a innovative idea? Contact us to discuss what we can realise together!