New design combines LNG operation with open-top sailing

We received an enquiry for the concept design of a 5000-6000-tonne deadweight multi-purpose vessel (MPV) that truly had to be multi-purpose. The ship would have to be able to sail “open top” and have a flush deck in order to carry project cargo. Furthermore, the vessel had to have ice class 1A and, in order to comply with the sustainability goals of the owner, a dual-fuel installation (marine gas oil (MGO) and LNG). All this had to fit within a compact and fuel efficient design.

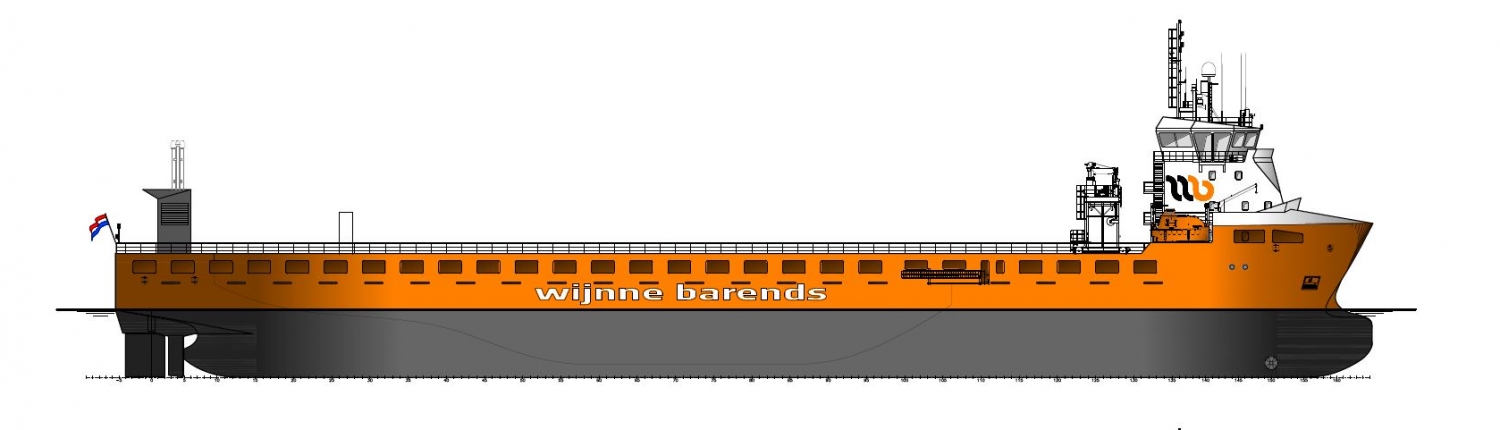

Obviously, the challenge of translating these demands into a feasible design was not an easy task. Especially as there was no existing design of this vessel type running on LNG with the possibility to sail open top. So when the first conversations with the Dutch client Wijnne Barends (Spliethoff Group member) about this new MPV began in 2018, our naval architects were driven to find a suitable solution.

In 2019, this resulted in signing a contract with Wijnne Barends for the contract, basic and plan approval design and principle 3D principle construction engineering of four multi-purpose vessels on LNG for its client UPM. The main purpose of these vessels would be to transport several kinds of paper related cargo, such as wood, pulp, and so on.

New technology comes with uncharted territory. When the first concept design was finished, there were more uncertainties than certainties. With the lessons learned while designing the LNG fuelled trailing suction hopper dredger Ecodelta and through consultations with independent LNG specialists and companies such as Wärtsilä, a working concept design came together in 2019.

The hull shape was optimised by using computational fluid dynamics (CFD) calculations and the layout of the vessel was adjusted to accommodate the placement of the LNG tank below deck. The superstructure and wheelhouse were placed in front to improve open top sailing capabilities. After the CFD calculations, the model was successfully tested at HSVA under the watchful eye of the client.

The vessels will be fuelled with LNG, which results in a significant (approximately 25 per cent) reduction of CO2 emissions compared with commonly used MGO. In addition, nitrogen oxides (NOX) and sulphur oxides (SOX) emissions will decrease approximately 85 per cent and 95 per cent respectively. The emissions of soot particles will also decrease by 99 per cent. All reductions shall be within the new emission limits for NOX and SOX of the IMO Tier III regulations.

The client’s requirements could be met through a diligent design process with all related parties and will now be technologically realisable. The challenges at some points were high and the feasibility of the designed solution has been more than proven in the model tests at HSVA. The result is a fine example of Dutch design.

The vessels will be built in China and are scheduled to be delivered in 2021 and 2022. Upon finishing the basic design, the Chinese WuHu Shipyard continued with the detailed engineering and the build of the vessels. We, however, will stay involved during the entire process from build to launch and christening.

Want to know more about this ship?

This article was also published in SWZ|Maritime’s July/August 2020 issue.