In the spotlight 3/4: How Conoship’s data-analysis reduces costs and CO₂ emissions

Conoship’s comprehensive experience, extensive design library, and highly qualified staff enable the company to carry out tailor-made consultancy work that meets each client’s specific needs. In this third article of a series of four, Conoship shares examples of consultancy studies where the analytical skills of Conoship International helped to support decisions about future designs, inefficiencies in operations, and investments.

Modern ships are full of sensor technology and contain a wealth of important data with unprecedented potential on many fronts. Conoship utilizes a wide variety of open and closed data sources to advise shipowners, charterers, port authorities, and various (financial) institutions.

Our engineers possess a comprehensive set of analysing skills to perform an extensive market analysis. Good analysis of data allows a shipowner to make decisions on combined knowledge rather than just assumptions. The results range from optimized designs, advice about fleet development to reduced costs to improved key performance indicators and increased efficiencies in the operations.

In this article, we share several of Conoship’s consultancy work where the analytical view of Conoship International helped to support decisions about future designs, operational efficiency, and investments for our clients.

5 benefits of data-driven decision-making

Data-driven decision-making refers to the practice of basing decisions on the analysis of data rather than purely on intuition. Data is abundant. By interpreting and analysing data, Conoship can substantiate or refute all assumptions and rules of thumb we applied in the past.

Data-driven decision-making outperforms guesswork. By using facts, metrics, and data Conoship will guide you to make strategic business decisions that align with your goals and objectives. The benefits of an extensive market analysis that empowers your company to make decisions about future designs, operational efficiency, and investments shouldn’t be left on the table. Those benefits include:

- Design optimalisation

- Operational efficiency

- Cost reduction

- CO₂ reduction

- Competitive advantage

Optimise ship designs

To define the crucial design requirements, Conoship’s specialists use data analysis to optimise the concept design. By analysing similar ships, or operations of the shipowner’s ships from recent years, Conoship’s specialists look at whether the client’s design assumptions, often based on gut feeling, are actually correct. This is data analysis to support the concept design.

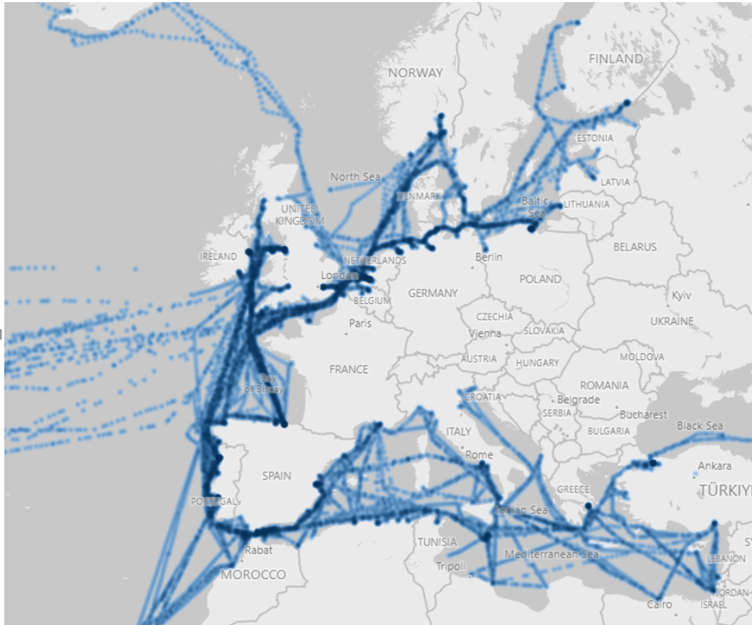

Another way Conoship is analysing data is to see how well a ship actually performs compared to the design principles. We then look at data we can get from public sources, such as AIS data and data received from the ship owner. We analyse all the data to see if we can trace the data back to the weather conditions and if this information gives input to make better predictions for new ships.

Currently, our research team is participating in the research project Transferring Operational Data into Design Information for Ships (TODDIS). A very clearly data-driven research project that investigates how sensor data with advanced algorithms can be effectively used for innovations in ship design. Conoship is one of the partners of more than ten companies and institutions in the TODDIS project, including:

- NHL Stenden

- TU Delft

- Rotterdam University of Applied Sciences

- Amsterdam University of Applied Sciences

- Royal Wagenborg

- Royal Van Oord

- Damen Shipyards Group

- C-Job

- Royal Navy

TODDIS focuses on developing tools that make data practical through algorithms in optimising ship designs. These tools, applications and software will be available as prototypes.

Fleet development

Faced with long-term changes in market conditions, staff availability, staff age and training, and technical developments, a new vision for fleet development is required. Based on market analysis, area of operation, earning capacity, and costs, Conoship develops new concepts for fleet and equipment.

As an operator, you have a clear vision of how to develop your fleet renewal program. But is this an optimal solution? Analysing and combining all types of data provides Conoship’s consultants with the insights to develop an optimal vision for the fleet renewal program. Data analysis provides genuine insights for operators.

Inefficiencies in the operation

Another opportunity where we use data effectively is to see where the inefficiencies are in the operation. Certain vessels have relatively long waiting times because they sail too fast and therefore reach their destination too early. Or the vessels lie misallocated waiting for the next work.

If you look closely at this kind of data and combine it with data from the market, such as charter contracts, there are opportunities to better align ship operations themselves between two contracts or two ports. This is not only smarter for ship owners, but also for charters to lower the day rates and for port authorities to avoid congestion in ports.

Especially when a vessel is not operating, it is still emitting CO₂ but is not transporting cargo at that moment. So, without investing, costs and CO₂ emissions can be reduced by making efficiencies in the operation.

Standard vessels

The numbers from the data analysis form the foundation for the development of our new designs for standard vessels. The designs for the standard vessels came from market demand, but the numbers from Conoship’s market analysis underpin the design choices.

For the designs of the 3600, 3800, and 6300 tdw general cargo vessels our consultants analyzed a large amount of data, such as:

- What cargo is shipped?

- What are the sailing distances?

- What is the age of the cargo vessels?

- How big is the replacement demand?

- What are the specs of the vessels?

Even down to port and pilotage costs have been factored into the Conoship’s designs of 3600, 3800, and 6300 tdw general cargo vessels.

When Conoship specifically designs a vessel for a client, our team takes into account all the specific wishes and requirements of the client. For making a standard design, it’s important to provide the largest possible group with your designs. Making the final choice always remains human work, but the numbers from the data analysis form the basis for making the choice for the final design.

One more thing…

Are you ready to challenge your gut feeling with numbers? The outcome is a logical consequence of all the steps done by Conoship’s consultants. Data is in abundance. By interpreting and analysing them correctly, you can be sure you are investing in your next optimized ship design, and advise about fleet development to reduce costs to improve key performance indicators or increase efficiencies in the operations.

One more thing… did you know Conoship generates its own tools to analyse these data and reveal connections between these data?

In this third article, we shared the consultancy studies where the analytical skills of Conoship International helped to support decisions about future designs, inefficiencies in the operation, and investments. The next article will reveal Conoship’s expertise in the field of optimising ship production facilities.

| Curious or need some maritime expertise? Contact us to discuss what we can realise together!