From First Impressions to Final Reflections

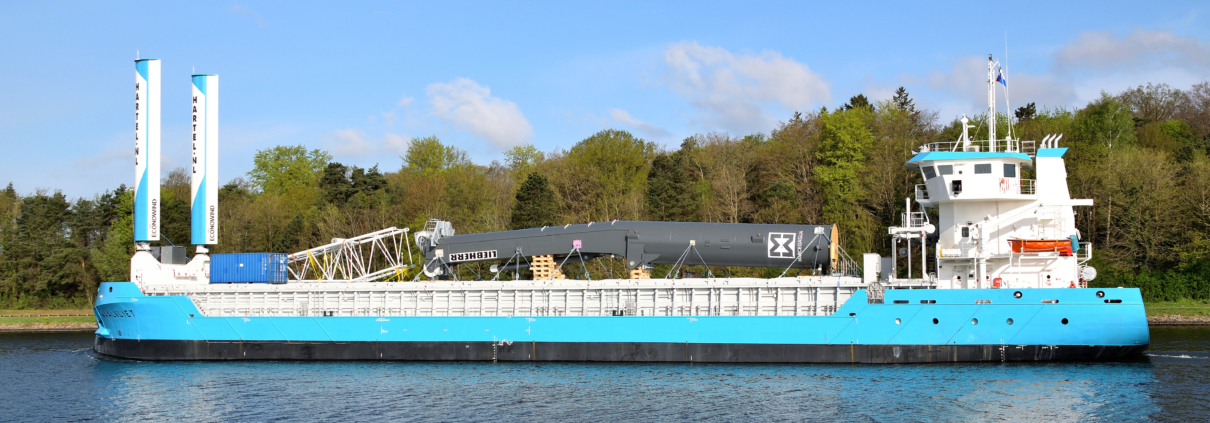

A mechanical engineering student from Hanze joins Conoship International for his internship. Eager to put his knowledge to use, he contributes to the research of Redox flow batteries while experiencing the maritime industry for the very first time.