Smarter ship design with FEM: Improving efficiency in structural analyses

Smarter ship design with FEM: Improving efficiency in structural analyses

Insights from a graduate study by Hotze van Doorn

Innovation in ship design goes hand in hand with structural integrity and efficiency. At Conoship International, pushing the boundaries of design requires advanced tools, and Finite Element Method (FEM) analysis is one such tool. Recent graduate research at Conoship explored how FEM can be applied more effectively during the early design stages, by delivering faster, smarter insights for safer and more sustainable vessels.

The goal: To develop methods for applying FEM effectively, even when limited design information is available.

Core theme: How ship designers can use FEM effectively in early design to optimize structural dimensioning.

Key insight: FEM is especially valuable for buckling checks in thin plate fields amidships, due to modern high-strength steel and larger span distances.

A graduate’s journey with Conoship

“My journey with Conoship began during the company fair at my university,” recalls Hotze van Doorn. “I was studying Maritime Technology in Leeuwarden when I met Klaas Visser (Manger Design & Engineering, and Naval Architect) at the Conoship stand. He offered me an internship, which turned out to be a perfect match.”

During his third year at university, he joined Conoship as an intern for his office placement. “I developed my skills as a structural designer and learned a lot from the team,” he says. After the internship, he continued working part-time every Thursday: “It was always a great experience, especially because every other Thursday ended with a team drink!”

What stood out most was Conoship’s commitment to supporting his academic development. “Whether I needed information for a project or real-world assignments to earn credits, the team was always willing to help. So when it came time to choose where to do my graduation thesis, the decision was obvious.”

“Early FEM analysis enables better decisions and stronger designs, without slowing down the creative process.”

The research: Tackling buckling in modern ships

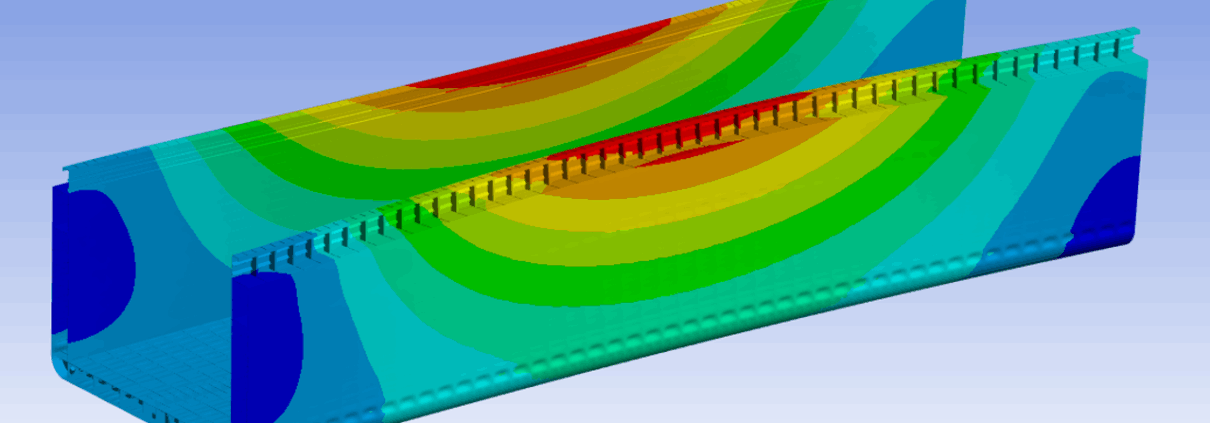

The graduation project focused on a pressing challenge in contemporary shipbuilding: buckling in the open plate fields of a ship’s midsection. As vessels increasingly use high-strength steel to enable lighter and more efficient structures, designers adopt larger frame spacings and thinner plating. The downside? Greater susceptibility to compressive stresses and buckling.

Using Finite Element Analysis (FEA), Hotze developed a method to identify vulnerable plate fields early in the structural design process, even when limited input data is available. “This approach helps designers make better decisions from the start, preventing buckling issues later on,” he explains.

Results: smarter, faster, safer

The research demonstrated that full-ship FEM in the concept phase is rarely practical, but selective modeling can deliver high value. By focusing on critical areas such as the cargo hold and applying targeted FEM checks for buckling, designers can strike the right balance between speed and accuracy. The study also provided practical guidelines and time-saving strategies for integrating FEM into Conoship’s existing processes.

“By refining how FEM is used, we can reduce modeling time while gaining key insights into structural performance. Ultimately, this contributes to safer, stronger, and more efficient vessels.”

Collaboration and looking ahead

For Conoship, this project reflects the company’s commitment to innovation and collaboration with future maritime engineers. The research of graduation students not only adds value to our design processes but also strengthens the bridge between academia and industry.

As Conoship continues to pioneer sustainable ship concepts and structural solutions, methods like FEM could play an increasingly important role. By making these tools faster and more effective, Conoship ensures its designs stay ahead in safety, efficiency, and sustainability.

If you are curious about this topic and would like to know more. Feel free to leave us a message on our contact page or contact Hotze directly.