This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Posts

Ecodelta – the new LNG consuming dredger

/in News /by Nanne SluisIn 2015, the project Ecodelta was initiated by Van der Kamp, a Zwolle-based dredging company and Conoship International. Ecodelta is a trailing suction hopper dredger which consumes liquified natural gas (LNG). This one of a kind dredger has two main objectives: recover valuable material from the seabed and create a greater depth of water. The vessel has a length over all of 134.10m, the breadth moulded 21.40m, a dredging draught of 7,770m, a hopper volume of 5900m3, a dredging depth below baseline of 35m and a Gross tonnage of 7560 GT. The ship has been designed by Conoship International and has been built by the Frisian shipyard Barkmeijer. Today, January 11th, the vessel will be christened. Conoship International congratulates Van der Kamp with reaching this milestone and thanks them for the pleasant cooperation throughout the project. Conoship International is very proud of the result and wishes the Ecodelta and her crew many safe journeys.

Environmentally friendly

Van der Kamp has signed a contract with the Port of Rotterdam Authority, in order to perform maintenance of port of Rotterdam until 2023. The final goal is to become the most sustainable port by replacing the fuel oil with LNG for shipping. Another advantage of LNG is cost-efficiency. The LNG tank of approximately 300m3, can store an energy which can be used in a period of two weeks.

Ecodelta is already meeting the upcoming regulations for emission reduction that will come in force in 2020. The usage of LNG reduces the emissions of CO2 up to 20% and NOx up to 85%. In addition, SOx is reduced to zero.

Read more about this ship:

Ecodelta 5,500 m3 TSHD on LNG (portfolio page)

CONOSHIP DECREASES ECOLOGICAL FOOTPRINT

/in News /by Nanne SluisCONOSHIP International decreases significantly the ecological footprint of shipping

Conoship International B.V. is in continuous innovation since 1952. The passionate team of Conoship International delivers the next level in ship design by introducing equipment which support the positive human impact on Earth’s ecosystem.

Since 2017, Conoship has been developing the eConowind-unit which is used to reduce emissions and fuel consumption. The unit has two foldable VentiFoils which create a superior thrust. Two, four or six units can be fitted on a vessel. In the case of two eConowind-units on a vessel with 5000 ton cargo, it is expected that the average fuel savings and reduction of emissions will be between 10 to 20%. The first trials of testing at sea have been successful and the results are promising. Therefore, Conoship International makes a big step towards emission free shipping.

Since 2017, Conoship has been developing the eConowind-unit which is used to reduce emissions and fuel consumption. The unit has two foldable VentiFoils which create a superior thrust. Two, four or six units can be fitted on a vessel. In the case of two eConowind-units on a vessel with 5000 ton cargo, it is expected that the average fuel savings and reduction of emissions will be between 10 to 20%. The first trials of testing at sea have been successful and the results are promising. Therefore, Conoship International makes a big step towards emission free shipping.

Conoship strives to add more value to the development of new as well as future equipment which will decrease the ecological footprint. In this manner, the organization advocates the philosophy of a global citizenship by initiating a forthcoming transition to the usage of more renewable energy systems. As a result, Conoship has launched and is involved in several research projects for alternative fuels. In the next years, Conoship will present designs for a fleet that will be able to fulfil any foreseeable future demands, up to zero-emission.

Methanol as marine fuel

/in News /by Nanne SluisThe potential of methanol as alternative marine fuel:

As member of the LeanShips project Conoship International plays a great role in the research of the possibility to use methanol as a marine fuel.

With its simple molecule, methanol has great potential to become the future marine fuel as it is safe to handle, environmentally friendly and can be produced from a large number of available raw materials from natural gas to biomass.

Conoship International already has a wide experience with assessments for conversions on existing ships but we also developed several new ship designs where the use of methanol as main fuel has a central role. These designs are made for new builds that will be powered with methanol as main fuel from the build or are easy to convert from one type of fuel to another.

Beside the technical part Conoship International has also developed a great Economic Assessment Tool. With this program several combinations of ship types, voyages and used fuel can be analyzed to compare alternative fuel options and to get an optimal prediction of the cost and returns for these scenarios.

Why methanol,

No sulfur and low NOx > near to zero emission.

Still liquid under ambient circumstances so easy and safe to transport and store.

Dilutes in water so no environmental harm in case of spills.

Already adopted within the provisional rules and regulations of Lloyd’s Register.

Widely available all around the world.

Can be used as fuel for combustion engines and also with a DMFC (Direct Methanol fuel Cell)

Is it Green?

With methanol as a fuel you are in compliance with Tier III regulations without any further aftertreatment.

Methanol has a very small ecologic footprint as it can be produced from a variety of renewable sources.

Methanol readily dissolves in water and biodegrades rapidly.

Conoship International will keep on investing in new designs and knowledge and we are ready to help you with questions about new solutions for your future ship propulsion.

![]()

Ontwikkeling prototype eConowind-unit van start

/in News /by Nanne SluisVentiFoil windhulpvoortstuwing voor schepen

Als innovatieve scheepsontwerpers zijn wij altijd op zoek naar nieuwe mogelijkheden die het schip net dat beetje extra geven om zich te kunnen onderscheiden van de rest. Om dit te realiseren onderzoeken we continu nieuwe mogelijkheden die leiden tot een beter schip. Een van deze onderzoeken is gestart in 2008 en heeft geleid tot de veelbelovende econowind-unit. Samen met het in 2016 opgerichte Econowind wordt nu het eerste prototype gerealiseerd, gesteund door Samenwerkingsverband Noord Nederland (SNN).

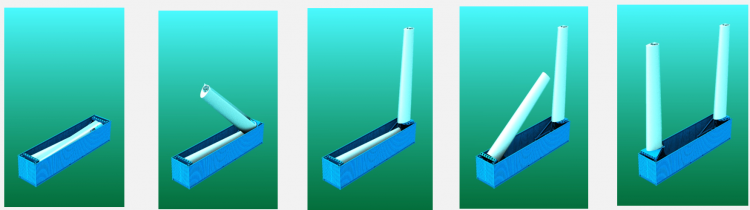

Een eConowind-unit bestaat uit een 40-voets container met 2 VentiFoils: vleugelvormige masten van 11 m hoog welke met innovatieve grenslaagafzuiging en ‘flaps’ voor aanvullende windvoortstuwing op schepen op zee kan zorgen. Het brandstofverbruik van de conventionele, fossiele brandstofvoortstuwing en dus de CO2-uitstoot, worden daarmee evenredig gereduceerd. De ontwikkeling van deze innovatieve VentiFoil windvoortstuwing is geïnitieerd door Conoship International BV en ondergebracht in een aparte onderneming eConowind BV, beiden gevestigd te Groningen.

Het gehele project bestaat uit ontwikkeling en testen van een 1:1 prototype van de eConowind-unit met speciale VentiFoil vleugelprofielen, de mechanische constructies (zwenken en inklappen), de besturing voor inklappen en autonoom varen. Voor een 1:2 schaalmodel (resultaat van een voorbereidend onderzoek, voorafgaand aan dit project) worden instellingen (zoals ‘zeilstanden’ in relatie tot windsnelheden) en werkingscondities (luchtafzuigparameters) theoretisch en proefondervindelijk onderzocht en vastgesteld. Met de resultaten van het 1:2 model wordt een 1:1 prototype van de eConowind-unit ontwikkeld. Het prototype wordt na sterkteberekeningen voor de vleugelmast, klapconstructie, behuizing en dekbevestiging ontworpen en gebouwd.

Gemiddelde besparingen van 20 tot 30% op brandstof en CO2-uitstoot zijn te verwachten, met het juiste aantal eConowind-units per schip. Ook de volledig autonome besturing van de VentiFoils, steeds optimaal afgestemd op de actuele windsnelheid en –richting, wordt ontwikkeld en getest op zee. Te onderzoeken en testen veiligheidsaspecten omvatten onder ander de constructie, montage aan boord en automatisch inklappen van de VentiFoils bij zware storm en te grote hellingshoeken van het schip.

Heerma Marine Contractors

Heerma Marine Contractors