Concept Design for Zero Emmision Shipping Presented at IMO London

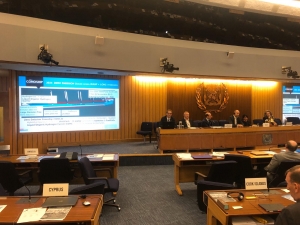

On Monday 11th of November, a week after winning the Dutch Maritime Innovation Award 2019, we informed at the IMO Headquarters in London the members of the 6th Intersessional Working Group on Green House Gasses (IMO ISWG GHG 6) on the actual possibilities of Wind Assisted Ship Propulsion (WASP) with the Award-winning eConowind-units and VentiFoils to enable Zero Emission Ocean going shipping.

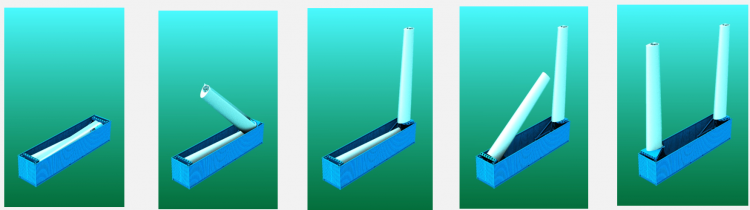

We presented in a ZESTAs mini-seminar in the Grand Assembly Hall of the IMO Headquarters (see picture), on behalf of Econowind BV that is a member of ZESTAs: the ‘Zero Emission Ship technology Association’. The development and principle of the eConowind-unit and VentiFoils were introduced very briefly, focusing on the practical application on the MV Lady Christina of WijnneBarends and the MV Ankie of Van Dam Shipping from Spijk. Retrofitting these wind propulsion units on existing vessels enables those vessels to reduce fuel consumption and CO2 emissions while maintaining the same speed up to levels of 20 % in favourable Bft 5 wind conditions. Actual developments were presented for new Short Sea Shipping designs of Conoship International, that can save more than 50% on fuel and CO2 emissions in favourable 5Bft wind conditions, by application of 2 VentiFoils of 20 m (foldable) on the foreship and an additional 2 Foldable VentiFoils on flatracks of 12 m on the hatches. These two can be handled with the hatchcover crane.

As various IMO delegates are representing countries with large bulkcarriers in their Flag-register, there was quite some interest in the possibilities of the 30 m VentiFoils XL (under development, scheduled for 2020/2023) that can be retrofitted on large bulk carriers in between the cargo hatches. Based on actual results with smaller VentoFoils, it can be expected that on ocean going bulkers sailing at speeds around 11 kn, more than 50% of propulsion power can be generated by six 30m VentoFoils XL at favourable Bft 5 windconditions, depending on size of the vessel and characteristics (and age) of the engineroom installation. The annual average savings in fuel and CO2 emissions are largely influenced by the windconditions of the operational area of the vessel. Saving up to 30% on average annually can be a realistic forecast for the example of the North Atlantic crossings.

This was rather positive news for the IMO delegates of the ISWG GHG 6, because their main focus in this weeks meeting was to discuss possible objectives, methods and regulations for existing vessels, to support and enable IMO’s ambition to reduce ‘the CO2 intensity’ by 40% in 2030. This means that the CO2 emission per ton-mile per ship should be reduced by 40% compared to the level in 2008, as an important step towards IMO’s main ambition to realize a reduction of 50% of the CO2 emission of the complete worldwide fleet of seagoing vessels in 2050. One of the discussed possibilities for the reduction per ship is ‘slow steaming’: reducing the speed of the ship so much that the consumed fuel (= CO2 emission) is 40% less per ton-mile than in 2008. The application of VentiFoils XL will enable the ships to reduce a large part of the CO2 emission at the original speed and will become a very interesting option to realize IMO’s ambition.

The other ZESTAs partners each presented their solutions for emission reduction:

- Futureproof Shipping: a 110 m inland navigation vessel that will be retrofitted next year with batteries and fuel cells and will than be sailing 100% zero emission;

- Nedstack: delivering fuel cells already up to 2000 kW and larger powers are under development;

- Hyon

- SPBES

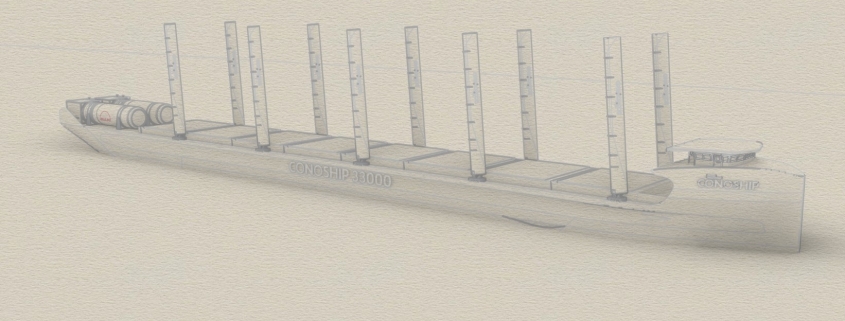

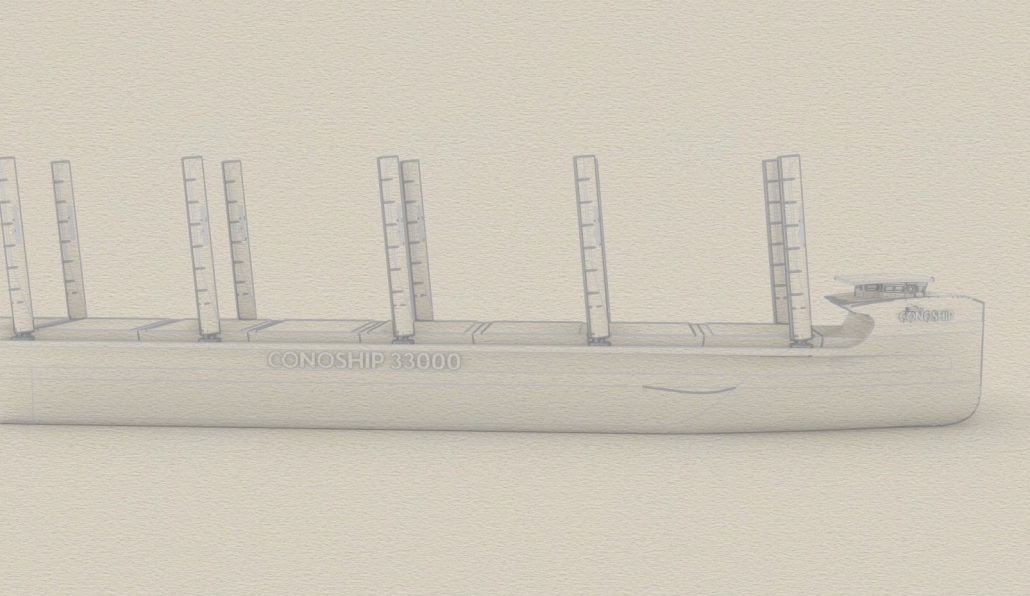

- Conoship – Econowind: eConowind-units and VentiFoils, plus a new Zero Emission Concept design for the ‘CONOSHIP 33000 ZE’ (Zero Emission) integrating the other zero-emission solutions in an Ocean Going Bulk carrier for the Great Lakes.

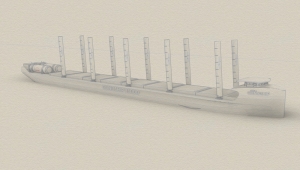

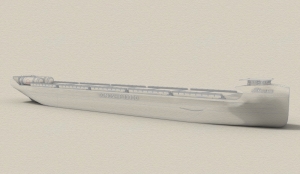

This new CONOSHIP 33000 ZE-concept of Loa = 220 m, B = 23,75 m and D = 14,50 m and 33.000 DWT, features ten 30m VentiFoils XL, that can deliver more thrust than required to sail at 11 kn, at favourable wind conditions of Bft 5 and more. The intended operation is to cross the North Atlantic at a speed of 11 kn in 100% Zero Emission mode, and to use the Large Diameter Propeller in 2 modes:

1 delivering the required thrust in the most efficient way, abt. 15% more efficient than a conventional propeller, driven by an electric motor with maximum output of 2500 kW ;

2 generating electric power from the flow of water in the wakefield of the ship while she is sailing at more than Bft 5: the propeller acts like a water-turbine driven by the passing water, turning the electric motor which will start working as a generator and providing electric power to charge the large battery-bank of 25 mWh (about 250 tons of batteries); the resulting speed of the vessel can be balanced around 11 kn;

At wind speeds below 5 Bft, the battery-bank can provide electric energy for the electric motor, and for longer periods the fuel cells will provide the electric power of the E-motor, fuel by hydrogen. The hydrogen will be stored on board in 2 liquid state at minus 253 degrees Celsius, in 2 tanks of 400 m3 that are actually in production at MAN Cryo in Sweden. The energy content of liquid hydrogen (LH2) per kg and per m3 is considerable, leading to quite feasible size of tanks that can be integrated in the design of the new Zero Emission ship concept. The rather limited amount of fuel is sufficient for the crossing of the North Atlantic, because a relevant part of required thrust for the speed of 11 kn will be provided by the VentiFoils, based on the annual statistic wind-distribution (of wind speed and – direction) on the North Atlantic ocean.

Application of 10 VentiFoils XL on this concept on this route, reduces the required size (and costs) of the Liquid Hydrogen system, enabling a technical feasible solution for Zero Emission Ocean going shipping. Economic feasibility will come closer with the progress of actual developments, on which the delegates of the IMO ISWG GHG 6 meeting will have quite some impact. With the presentation on the 11th of November in London, we aimed at gaining awareness of the above mentioned existing technologies and upcoming developments and we are looking forward to the outcome of the meeting.

Click here for the complete presentation given by Conoship International at IMO